High Quality Engineering Services in compliance with International standards in our ONE STOP SHOP

Welcome to the Harmon Group

Harmon Group is a family run business that is wholly owned by the Harmon family. The Group now benefits from a new generation of Directors, all serving over 20 years in the company, highly data driven & bring fresh Ideas and a sense of continuity and security to the Group.

With a global market place, Harmon Group produces complex and critical parts through to kits of parts, assemblies and sub-assemblies to customer specifications across many sectors in the modern market. Located within two manufacturing sites on the Ferndown Industrial Estate, Wimborne, Dorset, we are truly a ‘one stop shop’ for our customers.

Under our AS9100 rev D approval Harmon Group can offer precision CNC Machining, CNC Grinding, Fabrication and NADCAP accredited Surface Treatment and NDT service’s

Our Services

Manufacturing

Producing complex critical/vital parts using the latest 2, 3, 4 and 5 axis machining technology, with work management undertaken using Preactor v12 production management system and MRP data collection

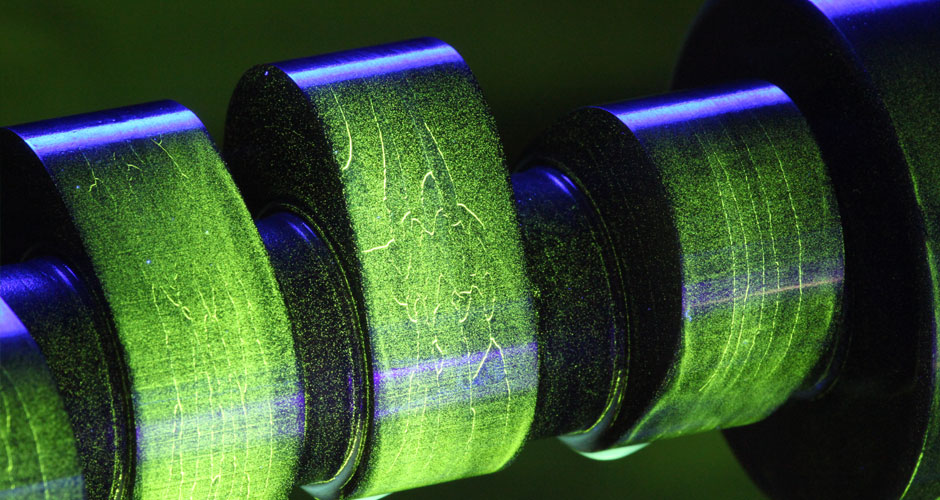

Grinding

A comprehensive range of grinding operations including CNC cylindrical and surface grinding, conventional grinding, vertical and horizontal honing, centreless grinding, carbide grinding and super-finishing.

Fabrication

Coded welding & Nuclear approval, with TIG, MIG and MMA processes undertaken from ferrous and non-ferrous materials backed up by our one stop shop on site surface treatments division and powder coat & wet spaying facility.

Treatments

Supported by Nadcap accreditation, we provide a range of surface treatments and level 3 standard non-destructive testing to aerospace standard including weld test.

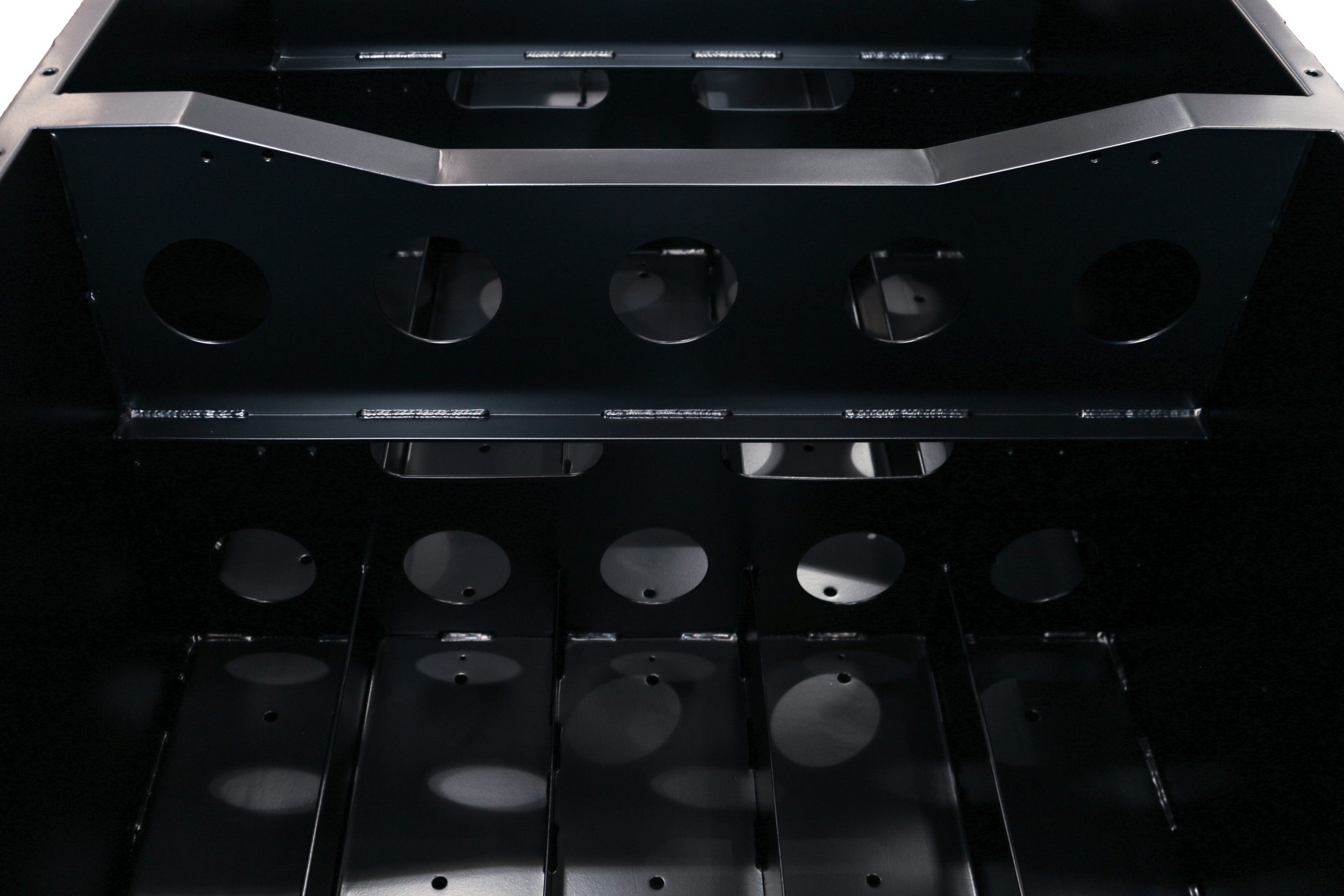

Assembly and Sub-Assembly

As part of our One Stop Shop service offered by the Harmon Group, we have expanded our facilities to improve our assembly area. To assist us in offering a full turn key service we have built a brand new clean room for assembly & sub-assembly, working to your designs, we can build, fabricate and put […]

Spraying Facility

Capable of large capacity 2.5m x 2m x 1.5m height & weights up to 750kg using the integrated overhead conveyor gantry.

All Powder & Most Paint Schemes Catered for With Traceability and CofC When Specified.

Our Approach

We aim to bring solutions to challenges, from initial NPI (New Product Introduction) through to delivery of the end product, using our ONE STOP SHOP to optimise value-added services and lead

times.

We believe in integrity, integrity in business, integrity in the products we manufacture, and integrity in our commitments. We build reliable, predictable, and trusted partnerships with our customers.

We offer life cycle support from development to aftermarket, order book updates, and continual customer communication as we believe that engaging in the short term builds for the long term.

Harmon Metal Treatments can use Chromic Trioxide beyond the sunset date of September 2024.

This will allow Harmon to continue supplying the following processes within our facility-

Chromic Acid Anodise (Chromium Trioxide)

Stainless Steel Passivation (Sodium Dichromate)

Chromate Conversion (Sodium Dichromate)

Dichromate Seal (Sodium Dichromate)

Paint (Strontium Chromate)

Passivation of (non-Al) Metallic coatings (Sodium Dichromate)

News

Latest update of our Harmon Group Expansion

The Harmon Group have completed the Extension of our Manufacturing Division, here is an image of the front of our new building, this extension has increased our shop floor capabilities by 10,000 sq feet and created 10,000 sq feet of new office space. We also have updated our assembly ability with a new dedicated clean […]

Read MoreHarmon Group’s Manufacturing expansion

The Harmon Group’s current expansion of its Manufacturing division is progressing well. The extension is well underway with the new assembly facility / clean room and new offices almost complete. This will allow for more manufacturing space to complement our current capacity, which includes the recent addition of a new Mazak Integrex i-400 with smooth […]

Read More